Electric powertrain cooling for a racing car

CFD studies of cooling system configurations with various components

In this project Optiphore sets off to help InMotion with the cooling of their electric racing car’s powertrain. The idea was to evaluate the performance of the liquid cooling system configurations, i.e. heat exchanger and condenser, under some demanding, real race, air flow conditions using Computation Fluid Dynamics (CFD).

Electric vehicles are becoming a very efficient and environmentally friendly alternative to internal combustion engine cars. Although their performance can nowadays be compared to that of fossil fuel powered cars, they present several challenges regarding electric energy storage. One of the major difficulties is the amount of heat generated by battery cells and the powertrain due to losses. Considering that electric vehicle power cells operate optimally at specific temperature ranges, cooling these components is crucial for the electric car’s performance and longevity.

InMotion is a students’ team based in the Eindhoven University of Technology. Their mission is to make electric car charging as fast and convenient as the refueling of petrol or diesel cars. The team plans to showcase the potential of electric refueling by joining in the Garage 56 class during the 24 Hours of Le Mans with a fully electric endurance race car in 2023.

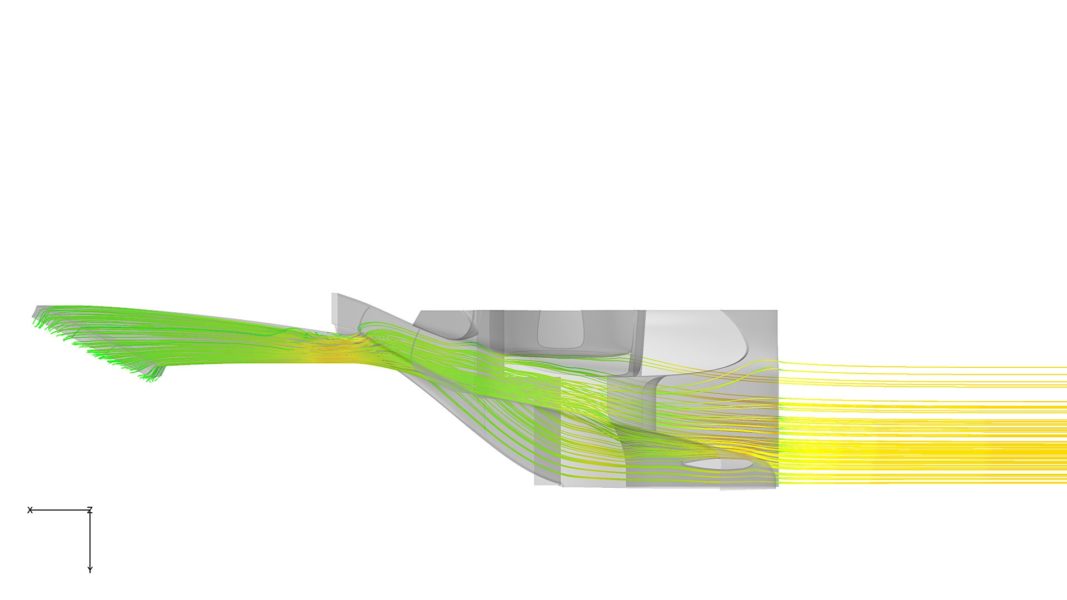

Optiphore is supporting InMotion’s efforts in various ways. In this case, the team was tasked to investigate the air flow inside the car's cooling ducts. The cooling system of racing cars works with natural airflow coming from outside and guided towards the car’s interior with specially designed cooling ducts. The air flowing outside a moving vehicle attains very high velocities, hence can be damaging for the car’s internal components. The air ducts are specially designed to carry a sufficient amount of air to its cooling systems.

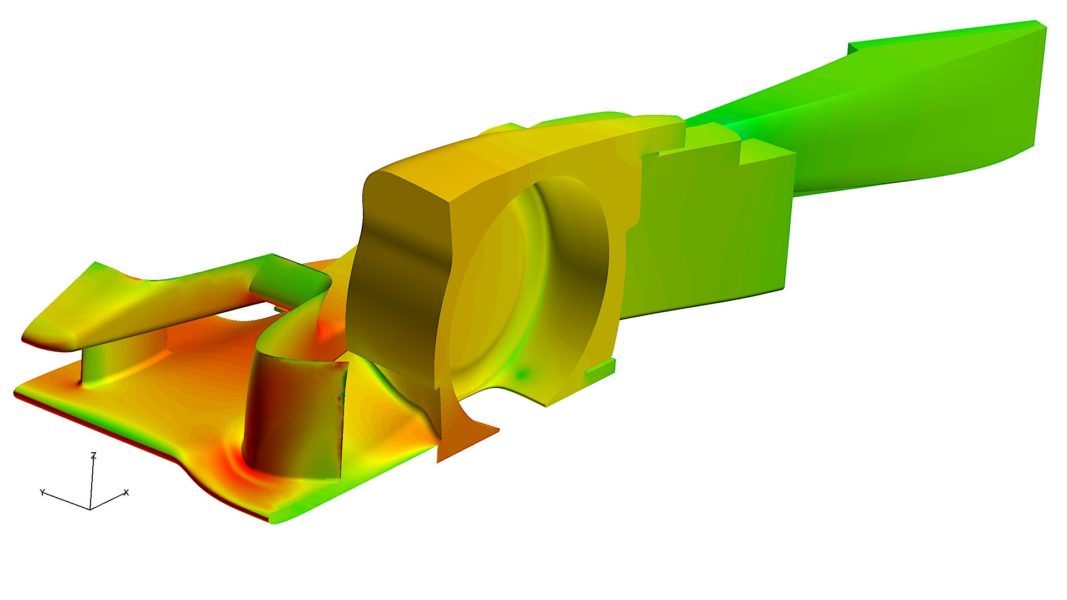

Optiphore performed CFD simulations of the airflow moving towards the car and within its interior to investigate the air's behavior within the cooling ducts. A detailed CAD model was provided by InMotion and subsequently modified by Optiphore in order to extract the fluid’s volume for the simulation purposes. To reduce the computational cost and the simulation runtime, all the car interior and part of the exterior were included in the CAD model. All simulations were performed with Altair's AcuSolve, utilizing computational meshes produced in Altair's HyperMesh. The initial results were correlated with experimental data provided by InMotion, verifying that the simulation conditions and assumptions were valid, and enabling Optiphore to perform subsequent simulations with different cooling strategies i.e. heat exchanger and condenser configurations.

While results derived from experiments are considered the benchmark data, experiments with different geometric configurations are very costly to set up and run due to the large number of physical models and the infrastructure required. Computational methods are proven to provide very accurate results, especially when undergoing a successful correlation study. Moreover, they can be employed at a fraction of the experimental study’s cost and time. With such a robust simulation strategy, CFD studies of configurations with various car components can be proven very beneficial.