Ship trim optimization

Fuel saving and greenhouse gas emissions reduction

Currently the maritime transport industry is under pressure to reduce its greenhouse gas (GHG) emissions. Trim Optimization (TROP) studies are a way to define the optimal cruising speed for a given vessel, ex. container ship, under certain loading conditions in order to minimize its drag and as a consequence its fuel consumption and CO2 emissions. TROP is conducted with the use of Computational Fluid Dynamics (CFD) software such as Numida’s Fine/Marine.

Global warming is one of the biggest environmental problems today, with atmospheric pollution, particularly greenhouse gas emissions, considered to be the biggest culprit. According to studies by the IMO “Maritime transport emits around 940 million tonnes of CO2 annually and is responsible for about 2.5% of global greenhouse gas emissions”. The International Marine Organization (IMO) has been working to reduce the shipping industry’s impact on environmental pollution since the 1960s. Since the beginning of 2020 they have imposed tighter restrictions in the ship Sulphur oxide (SOx) emission limits.

Costly solutions to this problem include the use of fuel with low Sulphur content, or the installation of approved exhaust gas cleaning systems (scrubbers). However, these may prove to be unprofitable for older vessels that are difficult to retrofit. Trim optimization is a cost-effective solution to this problem whose benefits can actually be compounded with those of other solutions.

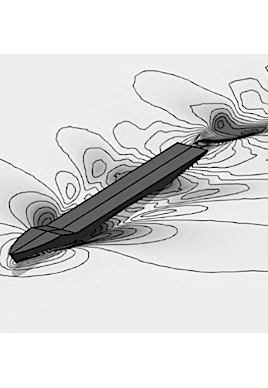

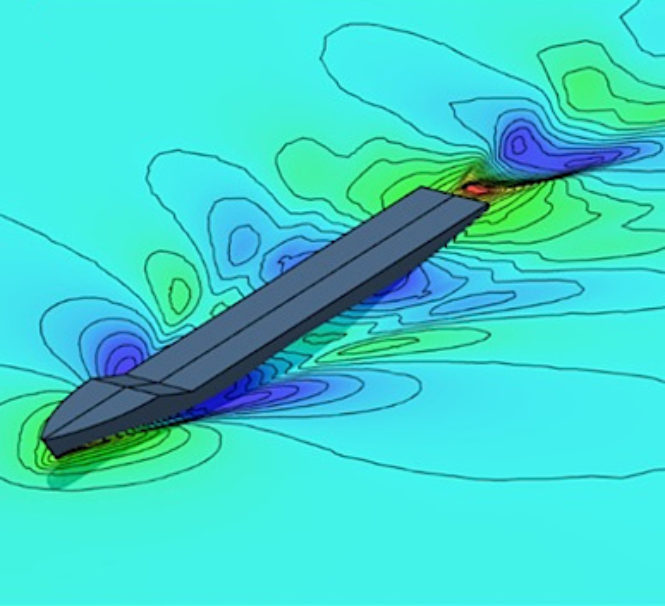

The total resistance of a ship’s hull is calculated as the sum of the viscous resistance due to its movement in water, and the wave-making resistance due to the wave pattern that forms on the water’s free surface. Depending on loading conditions a container ship or tanker may travel with different draft and trim values, altering the hull’s wetted area and the wave-making patterns. Therefore, the resistance of the ship’s hull at certain loading conditions varies with its cruising speed. Hence, a trim optimization study boils down to the drafting of guidelines for the vessels crew, on how to select the optimal cruising speed for given loading i.e. trim conditions in order to minimize the fuel consumption. At the end of the study those guidelines in the form of easy to use tables are the final deliverable.

From a computational point of view, to ensure minimal fuel consumption at various loading conditions, the optimal cruising speed must be evaluated for those very conditions. Obviously, this task requires numerous calculations of the ship’s total resistance at an array of draft, trim and velocity combinations, making this study computationally a very demanding project. Optiphore’s work focuses on:

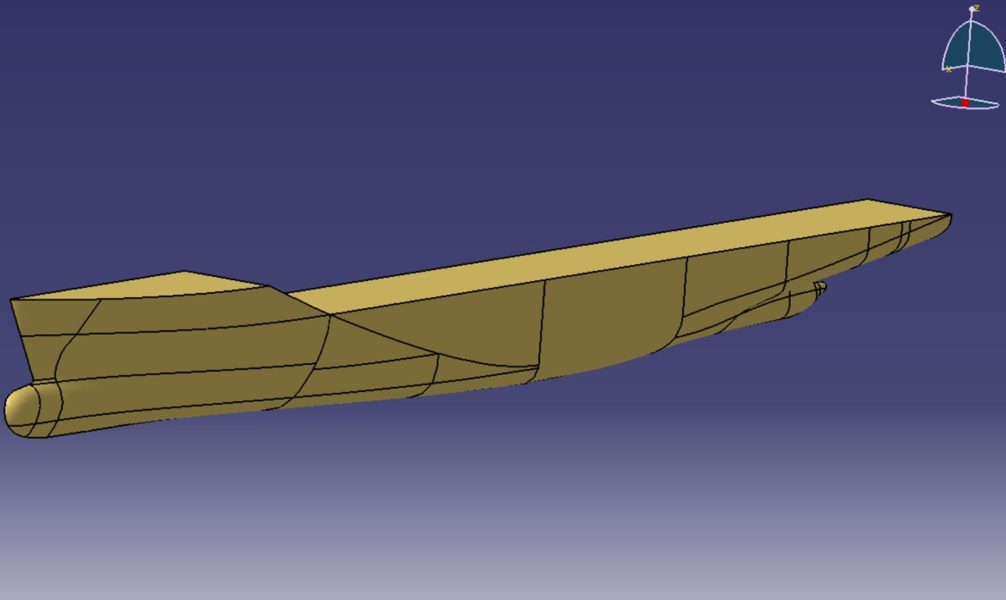

- The construction of the ship’s 3D hull design from its 2D body plan.

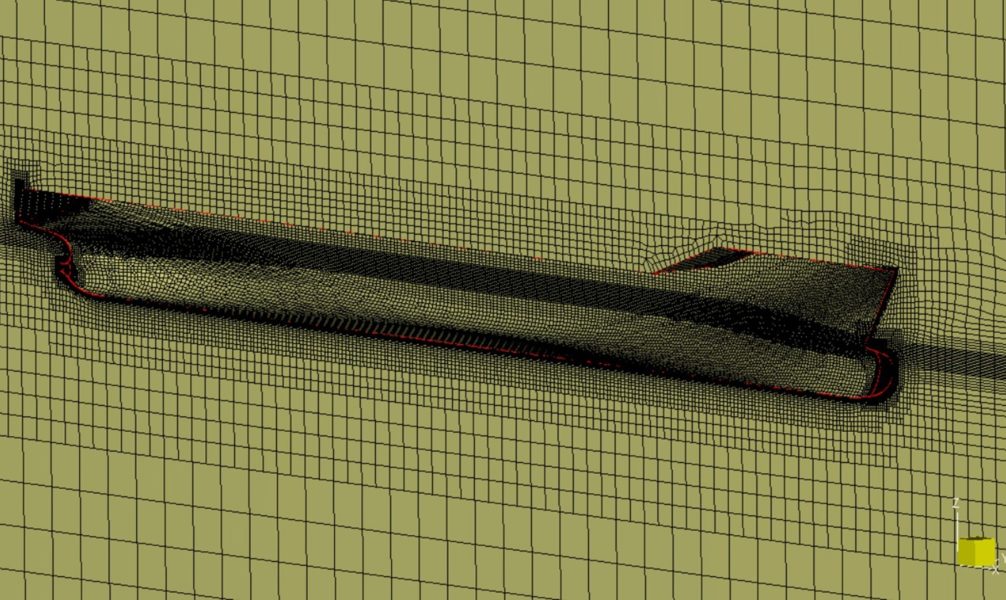

- The construction of a computational mesh around the ship and the water free surface and all loading conditions.

- The performance of CFD simulations of flow around a ship’s hull, at the selected draft, trim and velocity combinations.

- Evaluation of the ship’s effective power at all loading and speed conditions.

For the end customer, all the above translates into reduced fuel consumption and hence reduced operating costs as well as optimal use of an expensive asset. Furthermore, the minimization of CO2 emissions guarantees regulatory compliance and contributes to the maritime transport industry’s sustainability.